Advancing Recycling Technology to Secure our Future

Developing a sustainable, energy-efficient recycling process for diapers and other absorbent hygiene products.

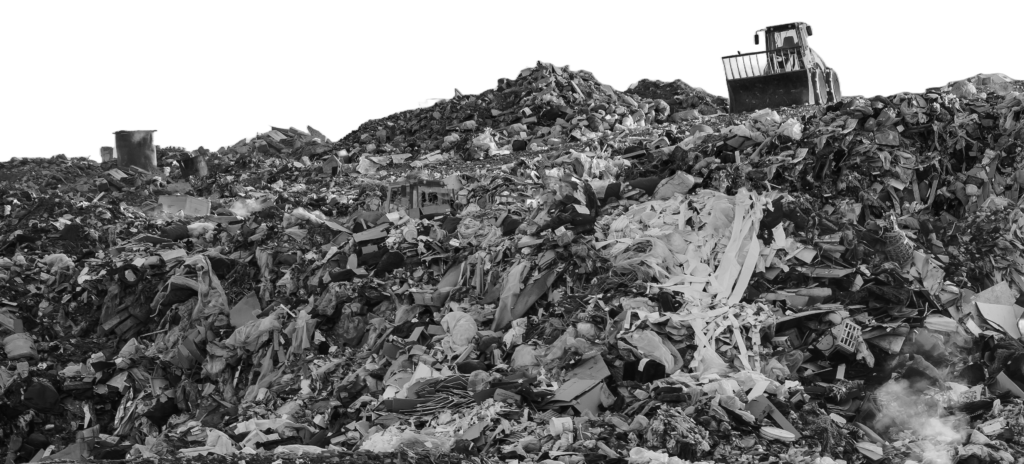

The Waste Challenge of Absorbent Hygiene Products

A single baby uses between 6-10 diapers daily. This amounts to an estimated 250 million diapers used daily worldwide. However, a majority of these waste diapers end up in landfills or incineration plants. Both of these approaches are not environmentally friendly. Current recycling methods include pyrolysis and incineration which use a lot of heat and emit dioxins and furans into the air plus other toxic fumes and ash.

There is a lack of sustainable technologies to recycle waste diapers yet demand for disposable diapers continues to grow.

Alkyl Recycling wants to find a solution to the billions of diapers that end up as waste every year.

250 million

diapers used daily worldwide

3rd largest

consumer commodity in landfills

500 years

to decompose

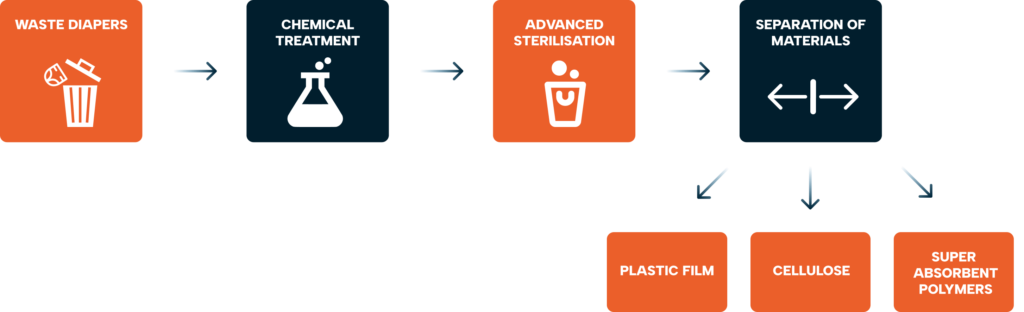

Alkyl Recycling’s process is a new sustainable approach that does not require the energy-intensive methods used in other solutions.

Our solution reduces energy costs and enables re-use of materials in a diaper

Alkyl Recycling is working on a technology that substitutes energy-intensive processes with innovative chemical techniques that preserve the structural integrity of polymeric material, thereby reducing the energy cost of heat and converting the waste into reusable raw materials.

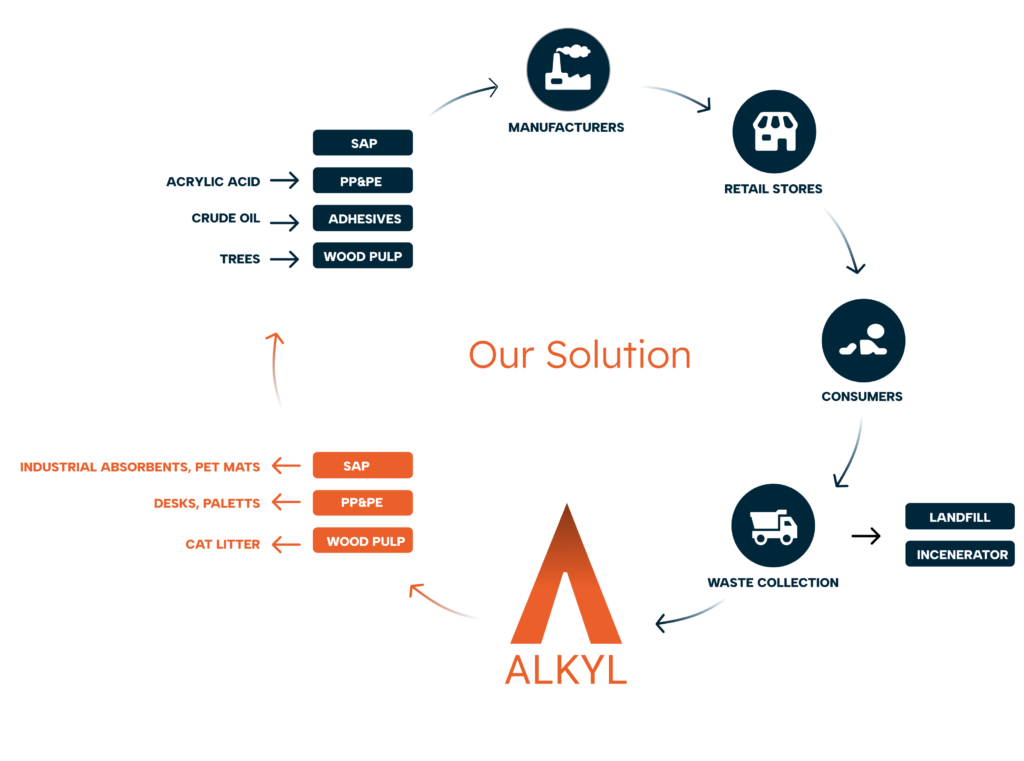

Our novel technology allows us to break down used diapers into their individual components, including plastic, wood pulp, and superabsorbent polymer. These materials can then be repurposed into new products, reducing waste and preserving valuable resources.

Be part of the future

We will deliver proven technology in the form of a model that integrates into the existing infrastructure of waste recycling companies and expand their recycling capacities.

Interested in keeping updated on future developments? Get in touch with us.

Diapers and other absorbent hygiene products will always be essential; we just need to manage the waste stream they generate.

Invest in the future! Be part of the solution

Our business model aligns with waste management companies’ need for proven technology backed by a strong business case. We will provide reliable technology that seamlessly integrates into their existing infrastructure, enhancing their recycling capacities.

Alkyl is currently funded by a mix of R&D Grants and LIOF Early Phase Financing.

OUR PARTNERS

Environmental impact

High energy inputs lead to unwanted greenhouse gas emissions. Alkyl Recycling offers a solution with a significantly lower environmental impact compared to traditional disposal methods like incineration.

Source: Comparative mLCA on waste treatment of diaper and incontinence material Revised Commissioned by Rijkswaterstaat Water, Verkeer & Leefomgeving (WVL)

Sustainable Development Goals

Our mission

Our mission at Alkyl Recycling is to lead the way in sustainable chemical recycling of complex waste streams, transforming absorbent hygiene product (AHP) waste recycling into a scalable, sustainable industry standard. Based at the Brightlands Chemelot Campus, our team of dedicated scientists is committed to converting complex waste streams into valuable secondary polymers for circular applications. We are at the forefront of sustainable chemistry in waste management, utilizing advanced chemical processes to reduce energy consumption and minimize toxic waste, driving a more circular economy.”